7/18/2014 6:02:03 PM

Advanced Solutions for Precision Machining

Advanced Precision Machining Solutions

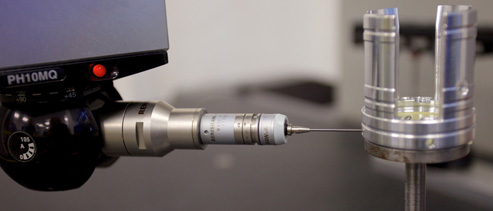

Precision Machining is in an ongoing development of new technologies, sophisticated mechanics and advanced manufacturing capabilities. A few matters are responsible for the significant change in the field: sophisticated machines that can be programmed according to advanced systems, innovative programs for axis processing, and more. Chips of various materials can be processed to obtain complex modules in a rapid manufacturing rate and maximum precision.

Efficiency is the name of the game. Machining becomes more efficient over the years, and it now offers advanced solutions for a variety of industries, from defense industry to the pharmaceutical industry. Here are some of the current advanced machining solutions.

Five-Axis Machine Centers (Milling)

After many years of using 3-4-axis machines, the time has come to step up to the next stage of 5-axis. This is a professional ability and the key to reduce processing time and improved surface processing. Five-axis machining involves indexical and simultaneous 5-axis machining, which are designed to achieve a precise processing of a variety of raw materials.

Engraving Combined with Milling

Today, engraving combined with milling is feasible; it thereby maximizes the process and manipulates the component in the best way possible.

Automation and User Control

Although there are still manual operative machines in the market, the tendency is to move to automatic machines that enable laying out manufacturing processes and precision machining while providing the planner and strategy builder with full control. In addition, the automated machines enable full quality control for the machine operators, who can thereby define preferred production processes at any given moment.

Advanced Systems

Precision machining market has been changed by unique software designed to build processing strategies that are responsible for the machine operation. Current software allows for calculating more accurate toolpaths while responding to the component’s size and complexity. Various programs assist precision machining process, from importing files and reading them in different formats, translating the files, saving the settings and programming the process. The use of "smart" programs in the field of precision machining enables saving time, maximizing the processing safely, while performing integrative work. The software allows for calculating toolpaths, addressing different models, and pre-setting various processes at all stages, being able to restore the process all over again.