7/16/2014 11:20:43 PM

Precision Machining Advanced Technologies

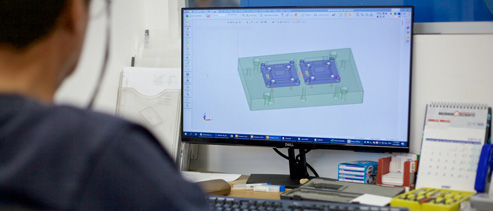

Advanced Precision Machining Technologies

The Precision Machining field is in an ongoing progression process; before beginning a new manufacture project, it is important that you become familiar with the new technologies in order to understand the new abilities in the field. Here is a brief overview of several technologies that have impacted the Precision Machining and changed the field entirely.

Five-Axis Machining

Sophisticated 5-axis machine centers have become more dominant in precision machining logistics centers and plants. The chrome five-axis machine has raised the level of finish and accuracy of the product and reduced its processing time. Prefer to work with plants which possess 5-axis milling machines, which lead to much better results than 3-axis machine centers.

High-speed machining

Part of the progression that largely influenced the machining capability also allows faster operation, which maintains uniform speed to achieve higher surface quality. The speed is made possible using HSC technology which allows distributing uniform load and eliminating sharp movements in the machine - thus reducing machining times significantly and allowing more accurate, uniform and fast manufacturing process.

Milling-Engraving in a Single Machine

It is crucial that the mechanical equipment of machining logistics centers be of the highest quality standards, if we expect successful manufacture. One of the most elaborated machines in the field is the MTM machine - this machine combines engraving and milling; it includes 10 spindles or more; it can also be scheduled for different machining times. The machines synchronize between drilling operations. You can adjust a variety of work programs to streamline the machining operation, for best results.

VoluMill Software

VoluMill can perform rapid removal of maximum raw material for ultra-high-speed machining; thus it allows machining of hard materials, which were previously very challenging. The point of using the software is to maintain a uniform tool load. The software consists of a sophisticated algorithm that can calculate the chip volume; thus, according to the volume of raw material, it adjusts the appropriate machine moves and maintains a uniform tool load throughout the entire process.